Boat building knowledge

Amateur boat building is a long journey full of unknowns. At least in 2007 when I built my sailboat, there was not too much information about it on the internet and finding somebody with experience, at least in Spain, was difficult. So back then, the best source of knowledge were books. Nowadays Youtube can be also very helpful although it won’t replace books. Some of the books I read back then are the following:

- Principles of Yacht Design by Lars Larsson and Rolf e Eliasson. This is my favorite book. Through its chapters the authors design a 40 feet sailboat and they explain the designing aspects of all the parts of the boat: hull, keel, rudder, mast, sails,etc. You will not learn specific construction techniques but you will understand how the sailboat machine does its work in its water/air medium. A certain knowledge of mathematics and physics is required to fully understand it, but even if you don’t have this knowledge, you will learn the basic concepts of yacht design and it will help you predict what behavior a sailboat will have just by seeing its plans and specifications.

- Devlin’s boat building by Samual Devlin. This is a book specific to the stitch and glue technique with plywood and epoxy. If you are going for this technique it can be very interesting to read.

- Elements of Yacht Design by Norman L. Skene. This book is part of the history of yacht design. It goes back to 1904. Only buy it if you are very interested in yacht design or curious about it.

- The Elements of Boat Strength for Builders, Designers and Owners by Dave Gerr. This book explains many of the construction techniques available (fiberglass, wood, aluminum, steel) and gives specific designing details (cross sections, joint details, material thickness). It relies a lot on empiric information, which is great to double check your plans or your calculations.

- Building a Foam Core Boat by Ron Palmer. A story about one particular amateur boat builder and his experience building a sailboat. Not technical but interesting to read about the things you might go through.

- Les Voiles: Comprendre, Régler, Optimiser by Bertrand Chéret. A deep book about sails shapes, trimming, etc. It is important to know what types of sails there are, how shape affects them, etc.

My experience is that sailing books and actual sailing complement each other. You will learn things in the books that you will not learn sailing, and the other way around is true. So try to get in a sailboat as much as you can and pay attention to its distribution, the materials, the structural design, what systems are used to trim the sails. I also went to the local yacht ports and took pictures of the sailboats when walking by the moorings. Finally, another great opportunity was to go to the Barcelona’s and Madrid’s boat shows to get new ideas.

Selecting the right boat to build

My recommendation is to make a list of the requirements you want for the sailboat. A few considerations here:

- Size. The size is probably the main requirement. It will largely affect the construction price, construction time, mooring price, the launch procedure (ramp, crane, travel lift), how easy to trailer it, habitability, etc. In my case I wanted something under 20 feet, easy to trailer it, with a small cabin for occasional sleeping.

- Construction technique. I’m no expert in boatbuilding, most amateur builders are not, so study the different techniques and restrict it to one you feel comfortable. In my case I chose stitch and glue technique using plywood, fiberglass and epoxy resin. This is a big constraint when looking for the plans but I felt very comfortable with it because I had already built a kayak using this technique. It is fast and cheap. The downside is that it is not the most aesthetically pleasant technique because of the hard chines and flat surfaces in the hull.

- Materials. Select the material for your sailboat according to your skills and the local availability. The main materials for amateur boat building are the following:

- Wood and plywood are cheap and easy to work with. The tools to work it are relatively cheap and available. The downside is that wood rots if it gets wet, so select the appropriate wood and seal it with a proper coating. In the case of plywood, make sure you use a phenolic plywood that withstands moisture, otherwise it will peel off. For small boats, wood will be the main material because it is light and you can get the needed cross sections with a moderate weight. Watch out for wood density, wood hardness, absence of wood knots, grain orientation and grain straightness, rot resistance, etc.

Marine grade playwood. Sheets are joined using a taper joint Straight grain and knot free timber for hull reinforcement - Epoxy resin: Epoxy is a great material, I think it is the material that makes amateur boat building easy and reliable. It comes in two components, you mix them and it hardens in a few hours depending on the epoxy brand, the thickness applied and the ambient temperature. There are many additives that can be used: mineral loads, wood loads, microspheres, etc. The main goal of these additives is to change the viscosity of the mix so it can be used for a specific task. Epoxy resin is vulnerable to UV rays from the sun, even if it comes with filters for this purpose. It will turn yellowish and brittle if exposed to sunlight, so give it the appropriate coating (varnish or paint). The main uses of epoxy will be:

- To wet a fiberglass cloth or mat. No additives needed since you need the lowest viscosity possible so the resin penetrates the cloth and glues it to the support.

- To seal the wood. Wood will rot if not properly sealed. Epoxy has a great bonding power so it will penetrate the wood pores and prevent water from soaking them. Again, no additives needed since lowest viscosity is desired. Apply more than one coating but be careful not to leave the epoxy harden too much or the second coat won’t attach properly.

- To glue two pieces. Add some additive to increase viscosity since you don’t want to squeeze out all the resin when pressing the pieces against each other. If the surface is porous, like unsealed wood, consider wetting the wood with pure resin before applying the additivated resin. If the bond is properly done, the bond strength of epoxy resin is higher than the wood strength.

- To make resin fillets. Resin fillets work the same way as metal welding works, you can join two plates by applying a long bead of resin between the plates. Applying a fiberglass cloth tape on top of the fillet is highly recommended to get full strength in the joint.

- Polyester resin: It is cheaper than epoxy but it does not have the same capabilities: less strength, less stiff, less durable, lower bonding power, etc. It is an alternative if resin represents a huge part of your budget, such as in a solid fiberglass hull using a mold, otherwise I do not recommend it.

- Fiberglass. It gives the tensile strength to the resin. It is easy to cut it with scissors or a cutter but it can be a bit messy since it unwovens easily. Therefore try to buy the formats that you actually need. It comes in different presentations:

- A woven cloth that comes in rolls. Widths from 1 m and up normally. The most common woven is at 90 degrees but you can get different angles and even unidirectional cloth.

- A non woven mat. I didn’t use it in the sailboat.

- A woven cloth in a tape format (10cm wide). Very useful for resin filets and to cover joints.

- Aluminum. Building a hull based on aluminum is an advanced technique for bigger hulls (50 feet and up). For small sailboats it will be used for the mast and a few hardware items.

- Steel is a strong material but heavy and prone to corrosion. For the hull, it will only make sense for big sailboats since the hull sections for a small boat would be too heavy. It can be interesting if you already have steel welding abilities and access to the material. For small sailboats you will use a stainless steel, 316 standard preferably, for stays and shrouds and their plates and for most of the hardware items.

- Wood and plywood are cheap and easy to work with. The tools to work it are relatively cheap and available. The downside is that wood rots if it gets wet, so select the appropriate wood and seal it with a proper coating. In the case of plywood, make sure you use a phenolic plywood that withstands moisture, otherwise it will peel off. For small boats, wood will be the main material because it is light and you can get the needed cross sections with a moderate weight. Watch out for wood density, wood hardness, absence of wood knots, grain orientation and grain straightness, rot resistance, etc.

- Intended use. It will greatly affect what type of boat to select. Some considerations to bear in mind:

- Will you sail solo? Two sailors? Three? The more hands in the boat the more sails you will be able to manage and the bigger they can be. In my case, when sailing solo, I can manage the jib and the mainsail due to their moderate size with respect to me (6 m2 and 12 m2). Sailing the spinnaker is a different task, it requires 2 sailors or even 3 for regatta conditions.

- Do you want to sleep in the boat? Do you need a toilet, a shower, or cooking? The habitability requirements of the boat will greatly affect the sailboat you select. In my case I just needed a small cabin with 4 basic bunk beds.

- What kind of waters will you encounter? Open ocean, closed seas, lakes? This will affect the minimum size of the boat or at least its stability requirements. I chose a wide flat bottom hull because I couldn’t find more options, and while this is great for racing downwind in strong winds, it makes the sailboat stability not ideal for cruising safely: The boat is stiff to heeling and will lose stability rapidly at a certain heeling angle. On the other side, round narrow hulls with a deep keel running the length of the boat are better suited for safe cruising, although they have a narrower cockpit too.

- What activities will you practice? Scuba diving, fishing, racing? This is important as all of those activities have their own requirements such as cockpit space, boarding platform, boat ladder, etc.

- Beachable. In my case, one of the Should Have requirements was to be able to beach the sailboat. Our coast in Valencia is full of long sandy beaches and waves allow beaching most of the time. For small sailboats, about 20 feet, this means a pivoting keel or daggerboard type keel. This increases structural complexity. For bigger boats I’m not sure this can be accomplished. Having this kind of keel also allowed me to launch the sailboat using a boat ramp.

- Cost. Needless to say that cost will determine what boat you will build. Boat length will greatly affect the construction cost and the mooring cost. I suggest you check your local yacht port tariffs.

Once the requirements are more or less defined, you can browse in search of your perfect boat. You will find plenty of free plans on the internet, the problems I find with these are two: construction details are often not defined and you do not have support from the boat designer. If you are an experienced boat builder or boat designer, then you can solve these problems, if you are not I recommend you to buy a set of plans from a boat designer that will give you the appropriate support during construction.

Finally, I selected the Puck 550 model by Paolo Lodigiani (BCA Demco). It is nice to see that the plans are still available online http://www.bcademco.it/

Preparations for the construction

One of the most exciting moments to me was to get the sailboat plans from the designer. At that point you move away from general ideas, problems, techniques and start to think about specific issues. The main tasks at this point are:

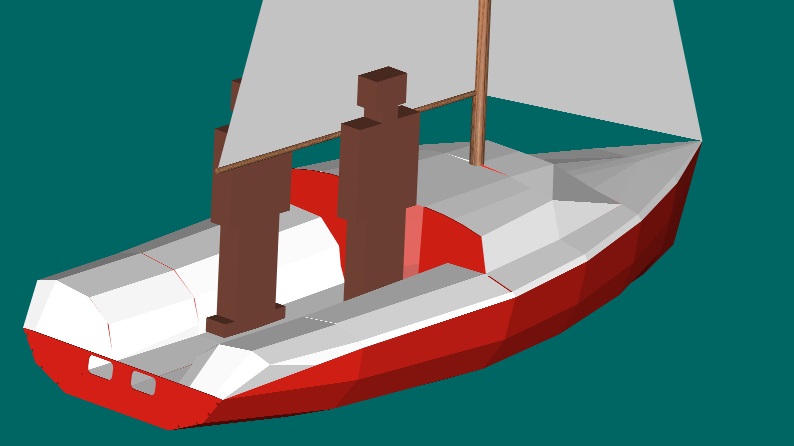

- Study the plans as much as you can. The more you study the plans the less surprises you will get during construction. In my case I received the plans in paper, so I spent a month drawing them in autocad and I even drew a 3D model. If you don’t have the autocad files I encourage you to ask for them to the designer in case there is, or start drawing them by yourself as I did. These will be very useful during construction to plan how many plywood sheets to buy, to calculate how much surface needs to be sealed with epoxy, to measure faster and with greater precision or to make modifications. These autocad drawings might be useful too if you have to register the boat as was my case.

3D autocad model - Buying tools is buying time, quality and safety. Do not hesitate in buying good tools. Electrical tools will save you lots of time. A good table saw is a Nice to Have. Sanding is very important and time consuming so investigate the different electrical sanding machines.

- Prepare the construction site. Some things to have in mind regarding the construction site:

- Be sure to have reliable water and electric power sources.

- Good illumination is critical during construction. When working with resins, sometimes you will not be able to stop a task and continue the next day, you will have to complete the task. On these occasions you might find yourself working till very late and a good artificial illumination makes the difference.

- A solid big table is really useful.

- Check whether the sailboat will be able to move out of the construction site. In my case I had to disassemble the door frames and tilt the sailboat to a specific angle.

- Cover all sensible surfaces from epoxy stains. Hardened epoxy is really hard to remove from many surfaces.

- Buying materials. I needed a couple of weeks to get all the plywood, wood, resins, fiberglass,etc. I used the sailboat trailer to transport the plywood. Be careful when storing the plywood so it is not bent, exposed to moisture, to the sun or to wood eating insects.

- Get some help. Unless you are a true hermit, it will be very important that your family and friends understant your project and support you. There will be some tasks where you will need an extra hand to do the job.

Motivation

It is not common for someone to build a sailboat, at least not in Spain where I am from. From what I have read and seen on the internet, it looks like there are countries where amateur boat building might be a bit more common. I am thinking about the United States, from where most of the books I have about this theme come from. But I guess that even in these countries, building your own sailboat is not common, so if you are thinking about it, there is probably a bundle of circumstances that have brought you to this point. I will share which were my circumstances.

First of all, I think that you are born for this. There are people that enjoy assembling/disassembling things just for the sake of it. In my case I recall as a child disassembling my brand new RC car which I had received as a Christmass present a few days before. I remember building a toy boat using tongue depressors and barbecue sticks, a kite with polyester cloth and fiberglass rods, a wooden wakeboard and fiberglass one, a 17 feet wooden kayak and so on… I think it is important that you ask yourself if you feel this way because building a sailboat will be a long project for sure and there will be tedious tasks, so the more comfortable you feel about doing manual tasks the better.

“I am me and my circumstance” as Ortega Gasset said. This impulse to build things is not enough, we are subject to our fate. And you might agree that this fate pushes us into certain directions. In my case there are a few experiences in my life that guided me down this path.

The first circumstance is that my grandfather and my father had small motorboats in our family town by the sea. We spent part of our summers driving these motorboats in the sea. Once you connect with the sea it is a strong bond. I see this true in people for the mountain, the desert or any special natural landscape.

Another powerful circumstance I had was reading Tom Sawyer and Huckleberry Finn books as a child. The adventure books have this power of taking you into a great adventurous endeavor without leaving your bed. The “problem” is that after you read them you want to live those adventures for real :)

Finally I met a school friend’s father who was a naval engineer and we got along pretty well. One of his dreams was to build a big sailboat and this finally got my attention!

In conclusion, boat building is going to take you at least several hundred hours, and even more than a thousand, so search inside for the right motivation. Sooner than later you will come through certain difficulties and depending on your motivation you will keep pushing or abandon the project.

It is normal to have doubts when embarking on unusual projects. As the saying goes “A journey of a thousand miles begins with a single step”. The saying applies perfectly to boat building. The first step can be to buy the sailboat plans, to buy some tools or to buy the sailboat trailer, at that point the journey has started, you are committed.

Add new comment